Rigid PCB parameter

| Size: | Nigeria |

|---|---|

| Power: | 26000㎡ |

| Voltage: | Nigeria |

| Hertz: | 50Hz |

| Capacity: | 16P |

| Space Area: | 9m*9m |

| Speed: | up(2m/s)down(5m/s) |

| Configuration: | Double oil cylinder system |

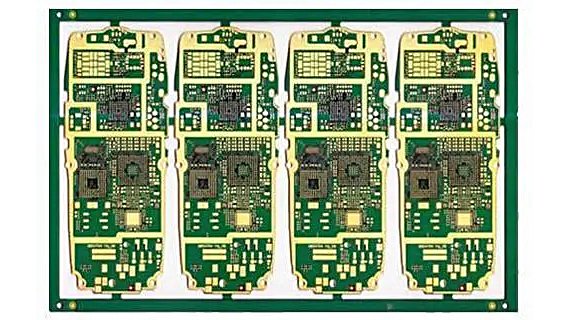

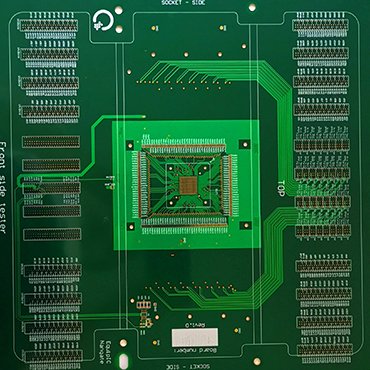

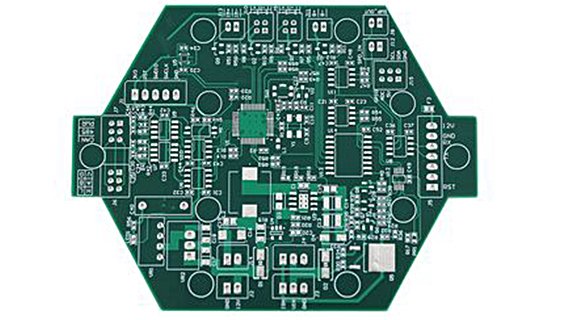

China Dragon Rigid PCB process

Our Rigid PCB is the most popular form of board in the PCB materials, and it’s easy to see why! You’ll find them in many products that consumers use daily, and they’re used in so many different ways. Our rigid PCBs are usually made up of several different layers, such as a substrate layer, copper layer, solder mask layer and silk screen layer. We adhesive and heat them, and make them joined together. Because of Rigid, it is solid, because of Rigid, it can’t bend or fold – it’s the perfect material for so many applications!

Many advantages of Rigid PCB

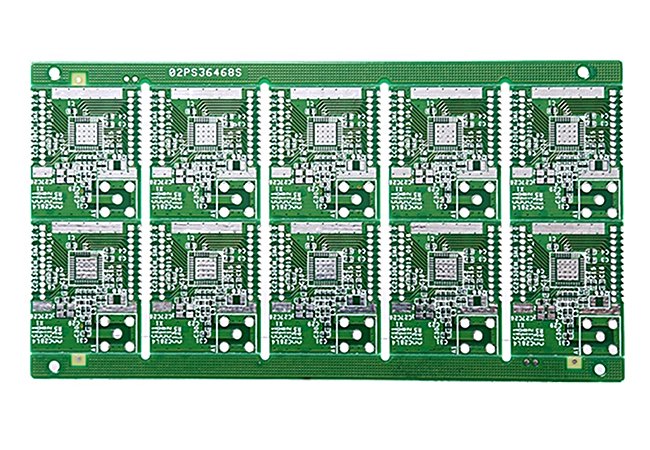

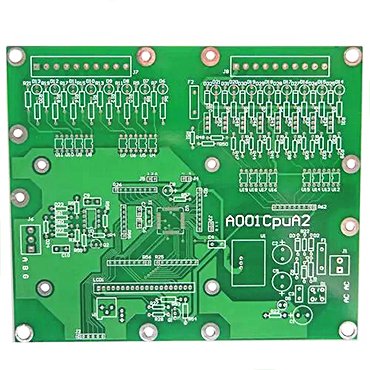

Traditional rigid PCBs are a great, cost-effective choice for your manufacturing needs. We’re in control of the cost of raw materials and we avoid waste, so you can be sure you’re getting the best value for money. We’re proud to offer you the low cost and high quality rigid PCBs you need!

When it comes to high-volume production of electronic products, traditional rigid PCBs are the way to go! They can be mass-produced efficiently and cost-effectively, making them a great choice for the big leagues.

Standard form factors are great for applications where standard rectangular or square PCBs fit well within the enclosure. Traditional rigid boards are perfect for these situations!

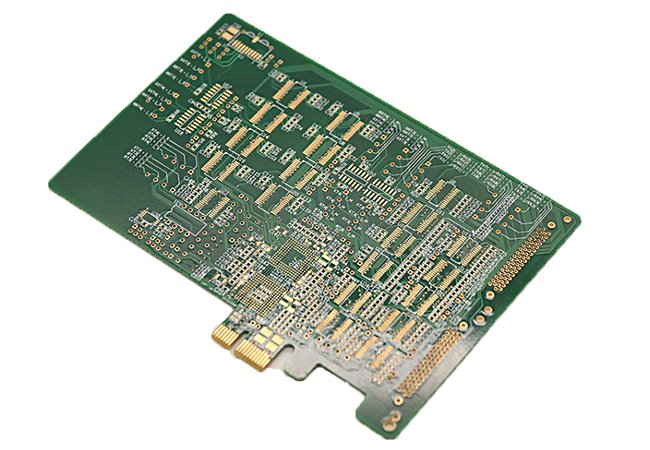

The process of Rigid PCB

Our Rigid PCBs are a form of circuit board that are solid and inflexible in their structure, which makes them incredibly durable and reliable. They’re made up of several different layers, such as a substrate layer, a copper layer, a solder mask layer and a silk screen layer, which are joined together via adhesive and heat, creating a strong and reliable product.

Rigid PCB cost control

It’s so important to take cost control steps in the early stages of PCB production! This is a great way to save our customers money, including during the actual circuit development stage. It’s also essential to be aware of the process steps and cost drivers for rigid circuit boards. Each process has additional costs in terms of process time, materials used, energy, and waste treatment. So, let’s make sure we’re keeping an eye on these things!

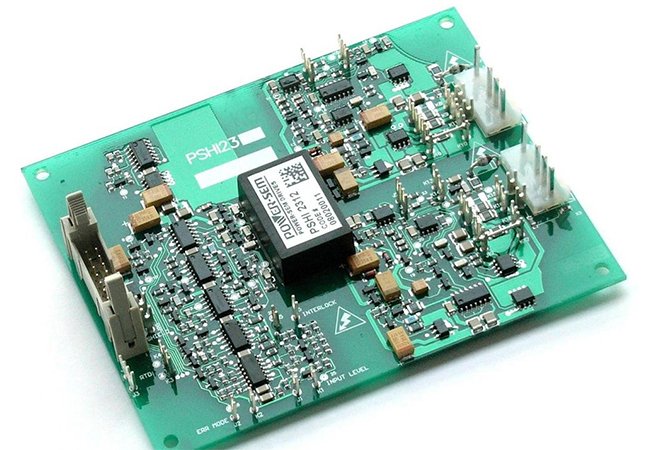

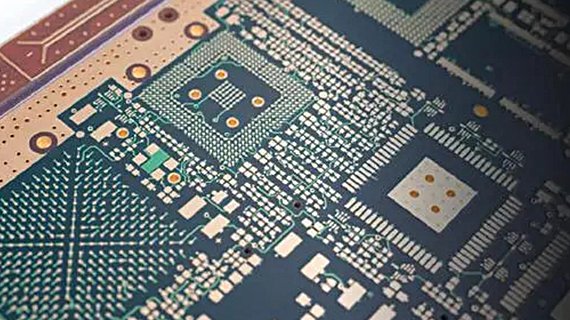

The application of Rigid PCB

Rigid PCBs are the perfect choice for a wide range of applications, including single-sided, double-sided and multi-sided PCBs. They are an excellent option for use in GPS equipment, computers, laptops, tablets and mobile phones.

And there’s more! They’re also used for medical equipment, including:

heart monitors

X-rays

CAT scans

MRI systems

If you’re looking for an option that is more durable, cost-friendly and able to produce large quantities, China Dragon Rigid PCB is the perfect choice! A professional PCB manufacturer, they’ll be your best bet for all your PCB needs!