Flex Rigid PCB parameters

| Size: | Nigeria |

|---|---|

| Power: | 26000㎡ |

| Voltage: | Nigeria |

| Hertz: | 50Hz |

| Capacity: | 16P |

| Space Area: | 9m*9m |

| Speed: | up(2m/s)down(5m/s) |

| Configuration: | Double oil cylinder system |

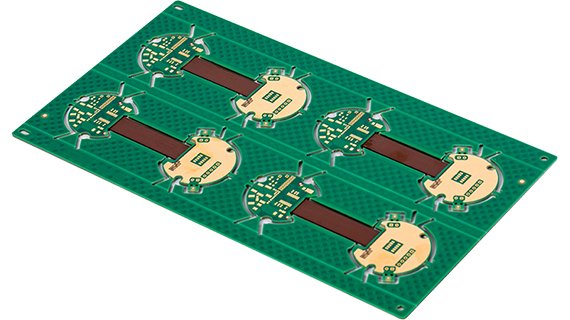

China Dragon Flex Rigid PCB process

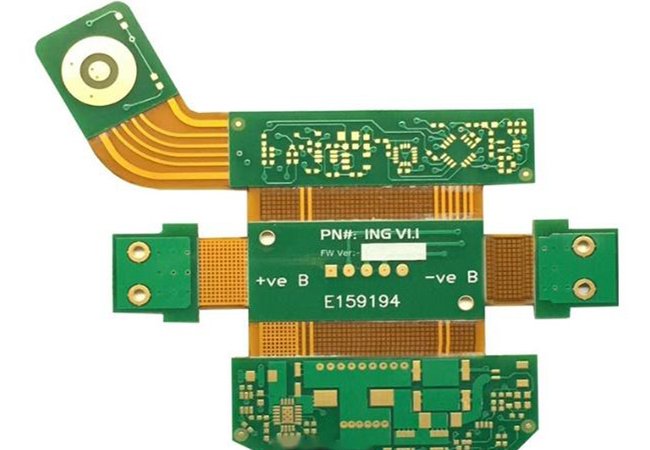

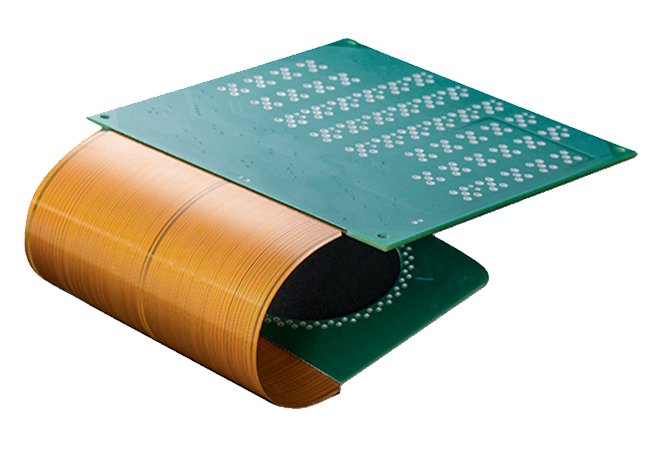

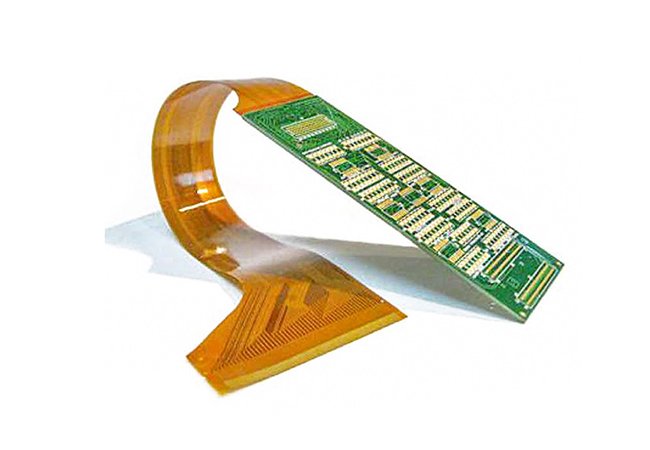

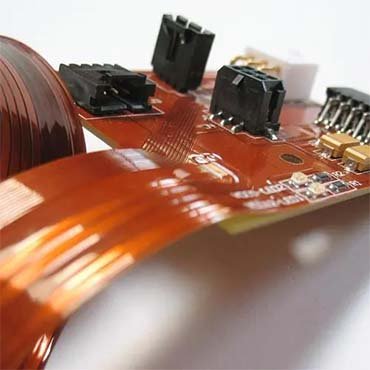

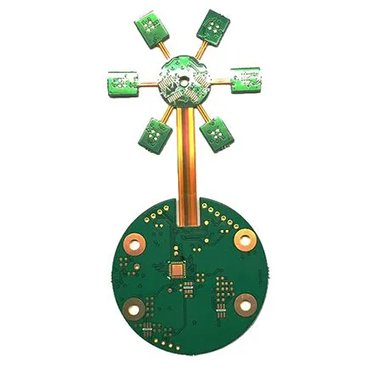

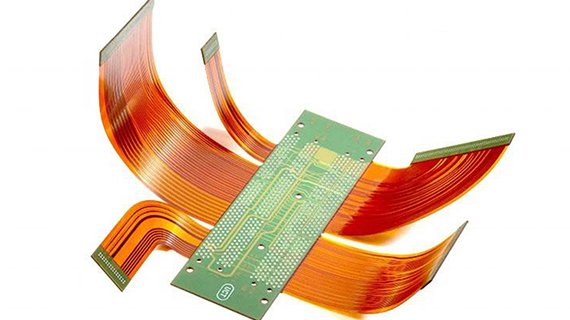

We’ve combined the best of both worlds! Our rigid-flexible circuit boards are the perfect solution for your needs. These innovative boards are a combination of rigid and flexible circuit boards that are permanently connected to each other, offering unparalleled advantages and a unique design.

Many advantages of Flex Rigid PCB

Get real-time supply chain data, access millions of ready-to-use parts, and take control of your components with ease.

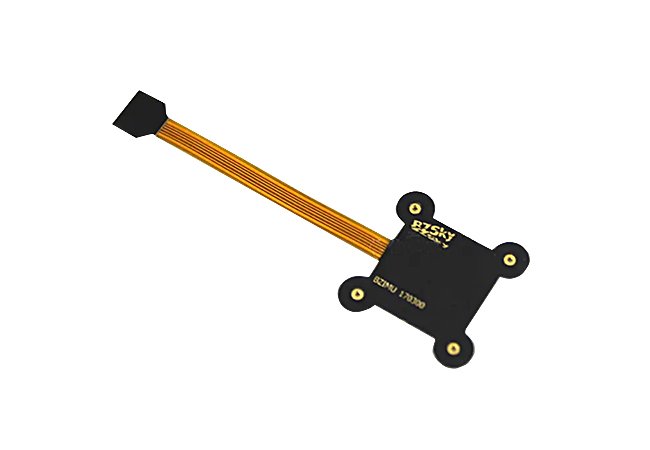

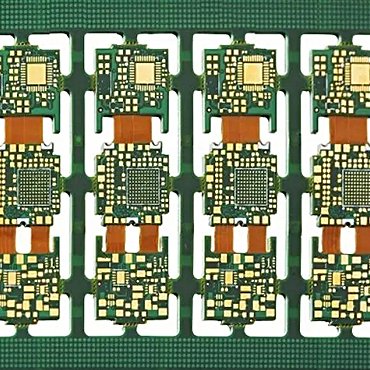

Our flex Rigid PCBs are an amazing space-saving solution! They eliminate the need for connectors and reduce the need for additional interconnects, making them perfect for compact and densely packed electronic devices. You can even fold or bend them to fit within tight spaces!

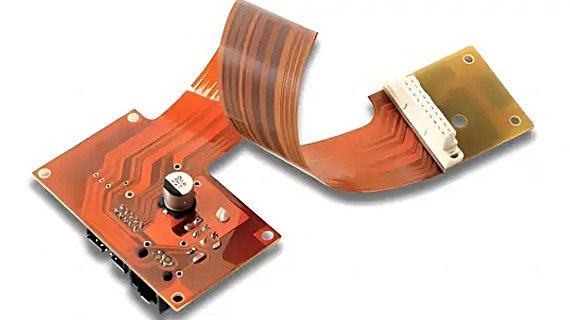

Fewer connectors means fewer potential points of failure, which is great news for overall system reliability! Flex Rigid PCBs are less prone to connector-related issues, which is another plus.

Our Flex Rigid PCBs are the perfect choice for applications in harsh environments! They’re designed to withstand mechanical stress, vibrations, and temperature variations, making them the ideal solution for your toughest challenges.

Our Flex Rigid PCBs are a fantastic solution for those looking to reduce assembly costs. The initial complexity of manufacturing is often outweighed by the benefits of having fewer components and fewer manual assembly steps.

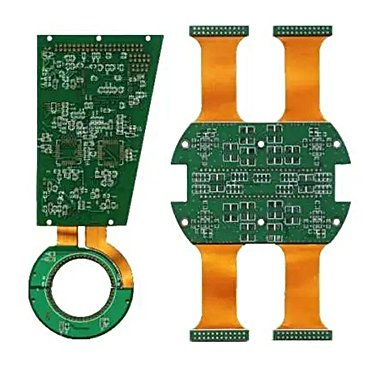

Our Flex Rigid technology is a game-changer! It allows you to create complex board shapes and three-dimensional configurations that would otherwise be impossible with traditional PCBs.

The manufacturing process of Flex Rigid PCB

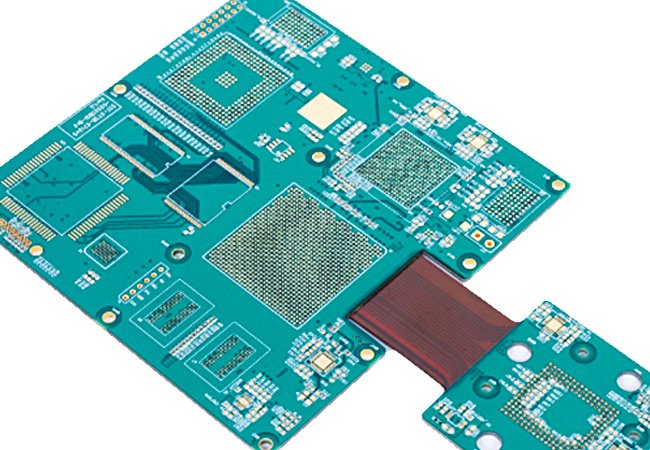

Our incredible flex rigid fabrication process is truly a sight to behold! It involves a series of steps, each more impressive than the last. We start with material preparation, then move on to pattern generation, etching, drilling, plating, flex-board cutting, and finally, electrical testing. This process is ideal for the construction of circuits in a number of industries, including medical, aerospace, military, and telecommunication.

Flex Rigid PCB cost control

We are committed to providing our customers with the best flex rigid PCBs at the best prices. To achieve this, we have implemented a rigorous cost-control strategy. We optimise the PCB layout, select the ideal material and plan the component density to reduce material costs, streamline the production process and monitor the supply chain to gain full control of our production costs.

The application of Flex Rigid PCB

Our amazing Rigid Flex PCBs are used in a wide range of industries in applications that require a combination of flexibility, space efficiency and high reliability.

Our amazing Rigid Flex PCBs are used in all sorts of exciting applications! They’re perfect for aerospace and defence, used in aircraft instrumentation and military equipment.

They’re also used in the medical industry, for implantable and diagnostic devices.

Our Flex Rigid PCBs are also used in the medical industry, for implantable and diagnostic devices.

If you need to order Flex Rigid PCBs, we are the best choice for you.