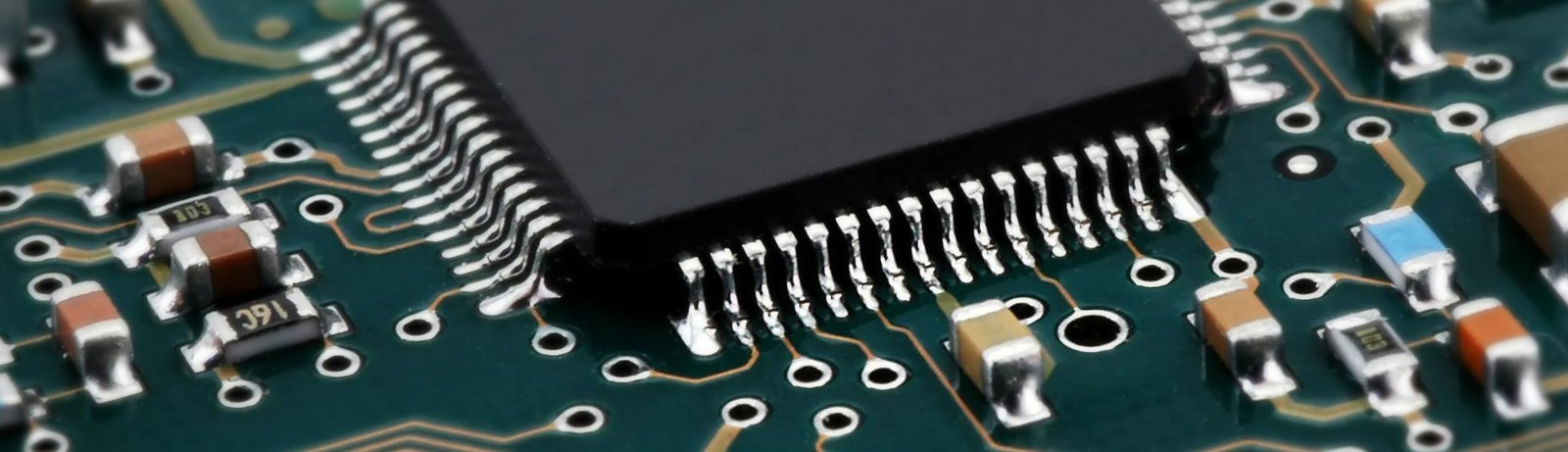

Industrial Automatio PCBA

PCBA stands for Printed Circuit Board Assembly. This is the process of putting pieces on a PCB board or plugging in a whole board. This is a common way of writing in the country. In Europe and the United States, the standard way of writing is PCB ‘A’, added “”, which is called the official terminology.

Our PCBA is one of the core components of the industrial automation system. Our PCBA has been applied to data processing, control communications and other aspects of many modern industrial enterprises to provide efficient, flexible automation solutions.

China Dragon PCBA is the perfect combination of reliability and precision, ready to respond to your needs at lightning speed!

It’s built to last with anti-vibration and anti-interference design, so you can count on it to keep going even in harsh environments.

It’s precision-made with advanced SMD and soldering technology, ensuring that every component is perfectly in place.

It’s flexible, supporting multiple component configurations and function expansion, so you can adapt it to your changing needs.

And it’s fast, thanks to an efficient production process that gets it to you quickly!

Multi-sensor data fusion and intelligent analysis

With the development of sensor technology, smart home devices are equipped with a variety of sensors, used to monitor the environment, user behavior and other data. PCBA technology integrates these sensor data and analyzes them through intelligent algorithms, so that the smart home system can better understand the user needs and realize intelligent automatic control. For example, when the system senses that the user is leaving home, it can automatically turn off electrical equipment, achieve energy savings

Security and privacy protection

Through the highly integrated PCBA technology, smart home devices can encrypt, store and transmit data to prevent data leakage. In addition, PCBA technology can also realize the integration of biometric technology and enhance the security of devices. For example, future smart home systems can identify the identity of family members and ensure the security of the system

energy conservation and environment protection

Using highly integrated smart home devices can make efficient use of energy. Through the combination of sensors and computing analysis systems, it can accurately judge the needs of different times and different users, so as to intelligently adjust the working mode of the device and avoid energy waste

The importance of PCBA in the smart home is mainly reflected in the following aspects

Strict implementation of PCBA test process is a key means to ensure product quality, reduce failure rate, improve production efficiency and ensure customer satisfaction. As an OEM factory with more than 20 years of experience in PCBA processing, it not only has advanced SMT production line and DIP production line, but also strictly controls the PCBA test process to ensure that every link is refined. We provide one-stop PCBA services from PCB design, circuit board manufacturing, component procurement, assembly, welding, testing to finished product delivery, committed to providing customers with high quality, reliable product solutions. Through our professional testing process, customers can safely deliver their products to us, ensuring that each product can run efficiently and stably.

Importance of the PCBA test process

PCBA is the core component of modern electronic products, and almost all electronic devices rely on it to realize its function. With the progress of technology, electronic products become more and more complex, and customers have higher and higher requirements for product performance, reliability and life. This requires manufacturers to not only pay attention to the manufacturing accuracy during the PCBA processing process, but also to strictly implement the test process to ensure the quality of the final product. In PCBA processing, if the test process is ignored or relaxed, it is likely to lead to unqualified products entering the market, resulting in economic loss of customers and brand reputation damage. Therefore, the strict implementation of the PCBA test process is an indispensable link in the electronic manufacturing industry.

consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.

consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.

consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.

consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.

consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.