Aluminum pcb process capability

| Size: | Nigeria |

|---|---|

| Power: | 26000㎡ |

| Voltage: | Nigeria |

| Hertz: | 50Hz |

| Capacity: | 16P |

| Space Area: | 9m*9m |

| Speed: | up(2m/s)down(5m/s) |

| Configuration: | Double oil cylinder system |

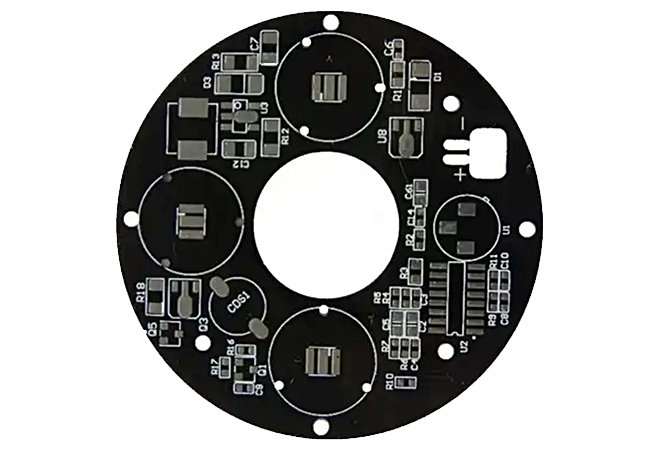

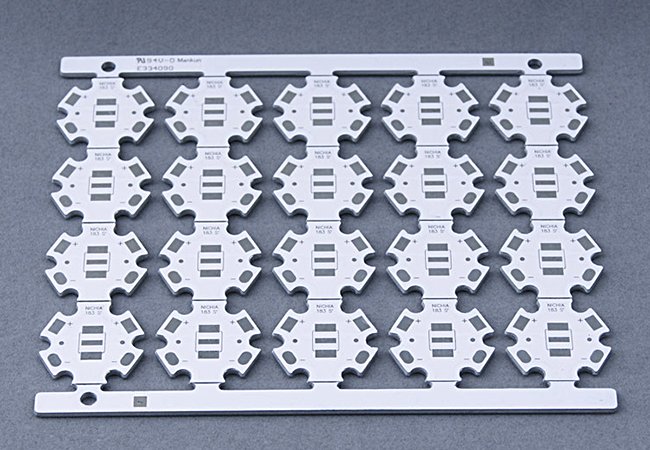

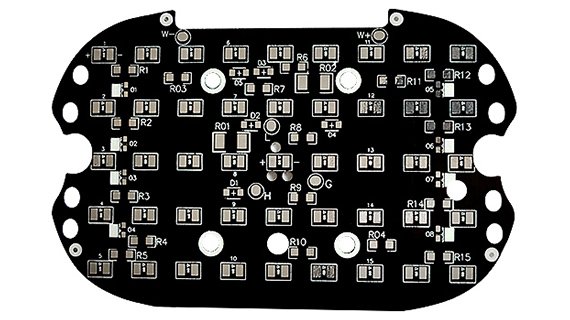

Aluminum pcb process

Aluminium PCBs are a fantastic feature of many MCPCBs. China Dragon aluminium PCBs are constructed with an aluminium core and standard FR4 material. This design is not only super efficient at dissipating heat, but it also cools the electronic components, which significantly improves the overall performance of the product!

Many advantages of China Dragon aluminum PCB

China Dragon chooses aluminium substrates for environmental protection. Aluminium is non-toxic and completely recyclable, which makes it the best choice for the earth. We are the leaders in green technology and environmental protection PCB. We make life better!

Aluminium has unparalleled thermal performance. It is a well-known fact that high temperatures are fatal to electronic devices. However, with an aluminium substrate, the main Chung effectively transfers heat away from the heating element or important parts, greatly reducing the potentially harmful effects on the circuit. This makes your equipment more stable and longer-lasting!

I’m going to tell you about the durability of the aluminium used in China Dragon products. Aluminium substrates are harder, stronger and tougher than ceramic or fibreglass substrates. This makes them more resistant to the risk of accidental damage during production, handling and even day-to-day use. This is a huge benefit!

Aluminum pcb manufacturing process

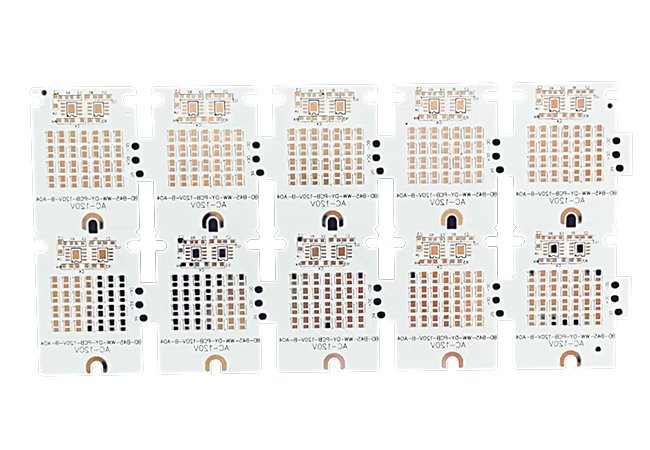

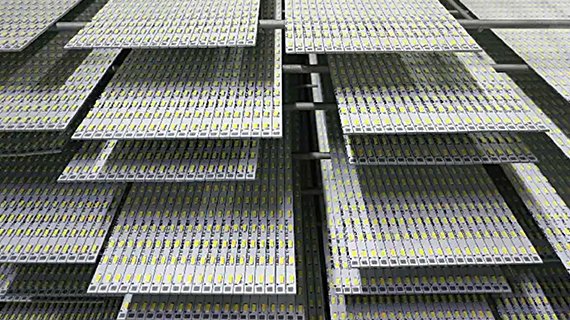

In China Dragon Aluminium PCB manufacturing process, we are proud to use two different surface treatment technologies in our manufacturing process in China. Let me tell you about our amazing production process for aluminium PCBs with OSP finish! It includes cutting, drilling, circuit design, acid/alkaline etching, soldermask, silkscreen, V-cut, PCB testing, OSP finish, FQC (Final Quality Check), FQA (Final Quality Analysis), packaging and delivery.

Secondly, for aluminium PCBs with HASL surface treatment, the production process includes cutting, drilling, circuit design, acid/alkaline etching, soldermask, silkscreen, HASL surface treatment, V-cut, PCB testing, FQC, FQA, packaging and delivery.

We are committed to providing high-quality and efficient manufacturing services, whether it is OSP or HASL!

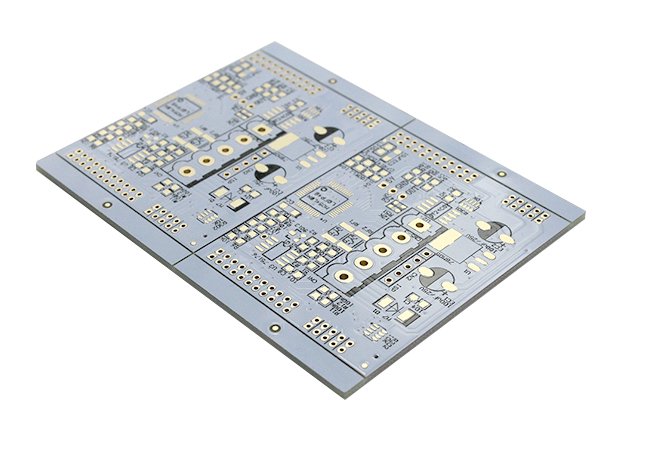

Aluminum pcb cost Control

We are thrilled to announce that we have successfully reduced the cost of aluminium PCBs without sacrificing quality! How did we do it? Through a comprehensive set of strategic measures, including design optimisation, material selection, efficient manufacturing processes, strategic sourcing and continuous improvement. Thanks to these strategies, our procurement experts and engineers have been able to make some impressive cost reductions while maintaining the high performance and reliability standards of aluminium PCBs.

At China Dragon, we are passionate about providing cost-effective aluminium PCB solutions that adhere to the highest quality standards. Our unparalleled expertise in design, manufacturing and quality control guarantees that you will receive the absolute best products on the market.

We have strict quality control

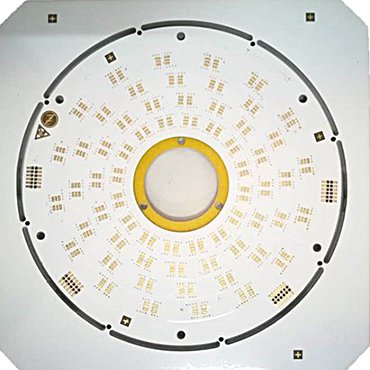

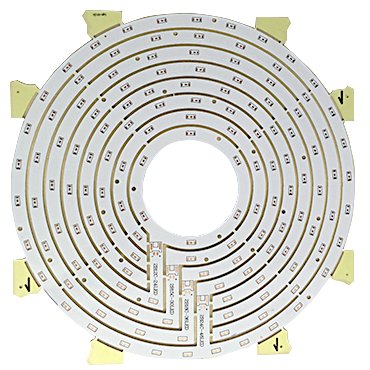

Aluminium PCBs are the best! They have a thermal operating point and can dissipate heat 10 times more efficiently than any other type of printed circuit board. China Dragon aluminum PCBs are widely used in so many applications!

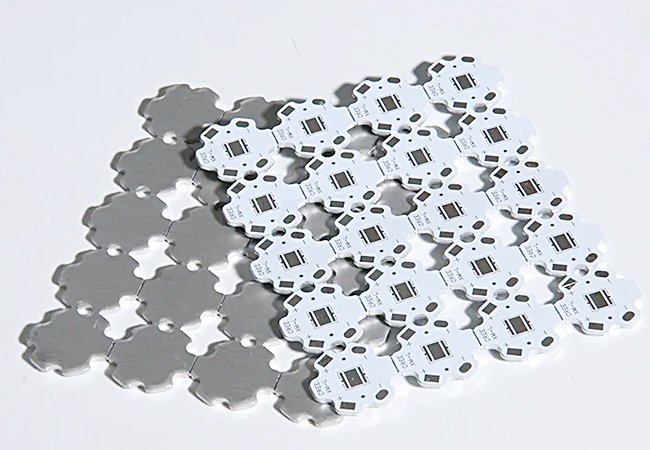

LED lamps: The possibilities are endless with aluminium PCBs! They’re used in most lighting applications, such as LED lamps for high beams, traffic lights, street or operating room lighting, tail light tools, landscape lighting, indoor lighting and surgical lighting. These applications are made possible by their compatibility with power converter designs, automotive instrument panels, power scanners and power transmission circuits.

Automotive equipment: There’s another hidden advantage to using aluminium printed circuit boards for switching circuits, power supplies or high-current automotive equipment. They preserve the life of the components due to their thermal stability!

Audio equipment is another great example of how aluminium PCBs are used. They are integrated with input, output and power amplifiers, making them an excellent choice for audio equipment.

Communication electronics: The amazing world of communication electronics is full of exciting possibilities, from power supply modules (e.g. bridges, solid state relays) to heat sinks.

If you’re developing any of the above products, we’d love to hear from you! We’re ready to support you with the highest quality aluminium substrate.